Monocrystalline zinc oxide nanorods | ||||

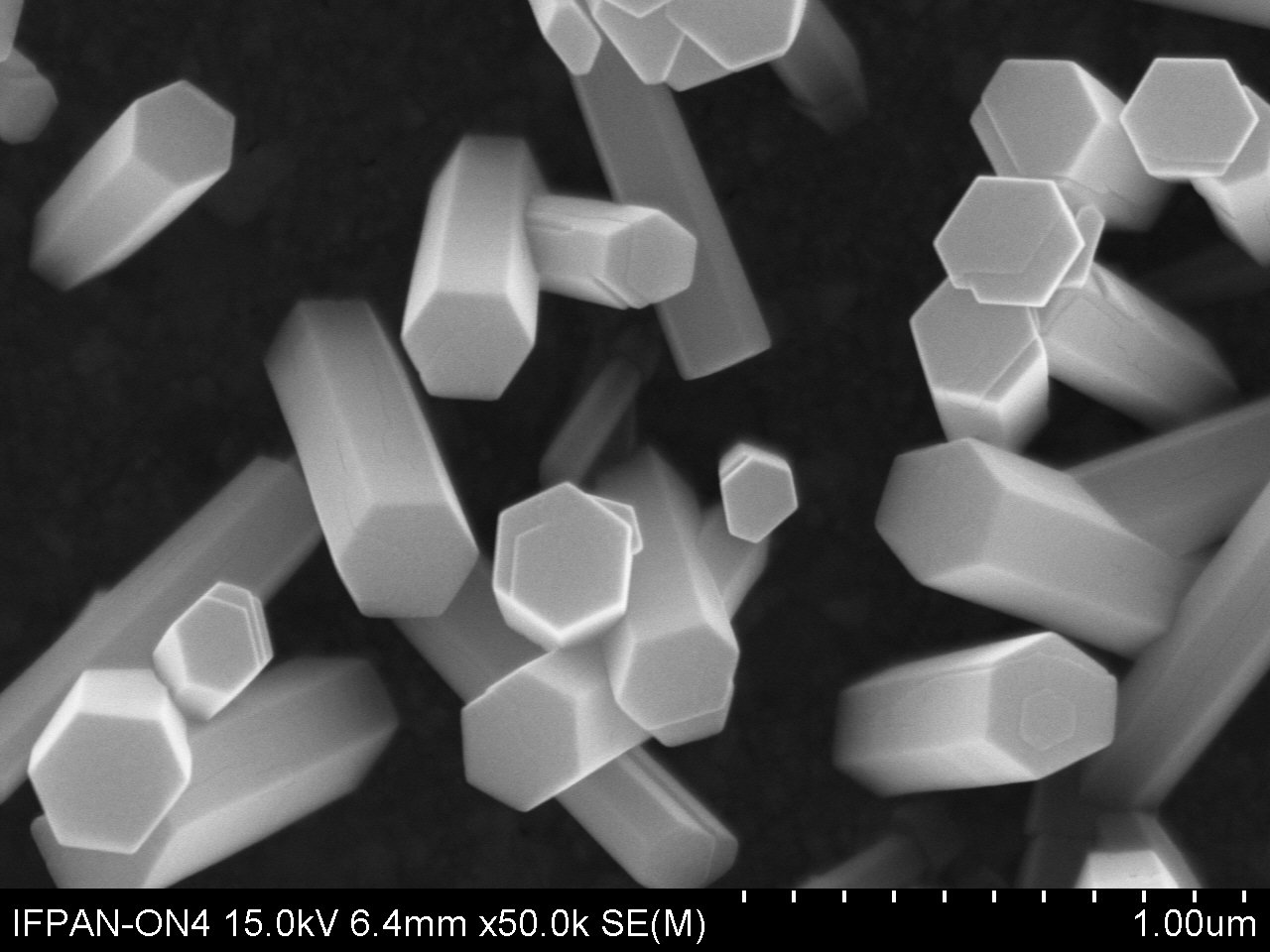

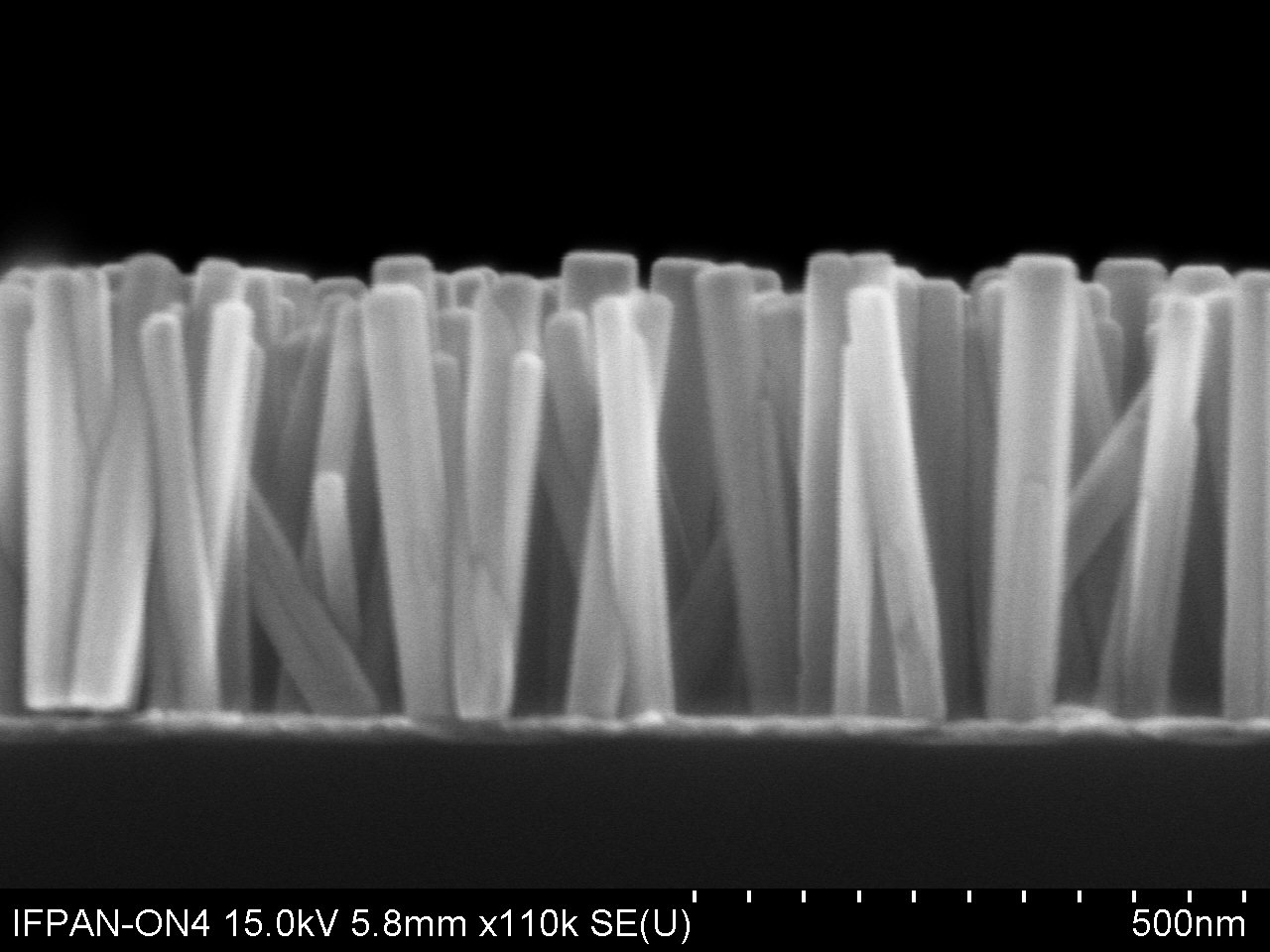

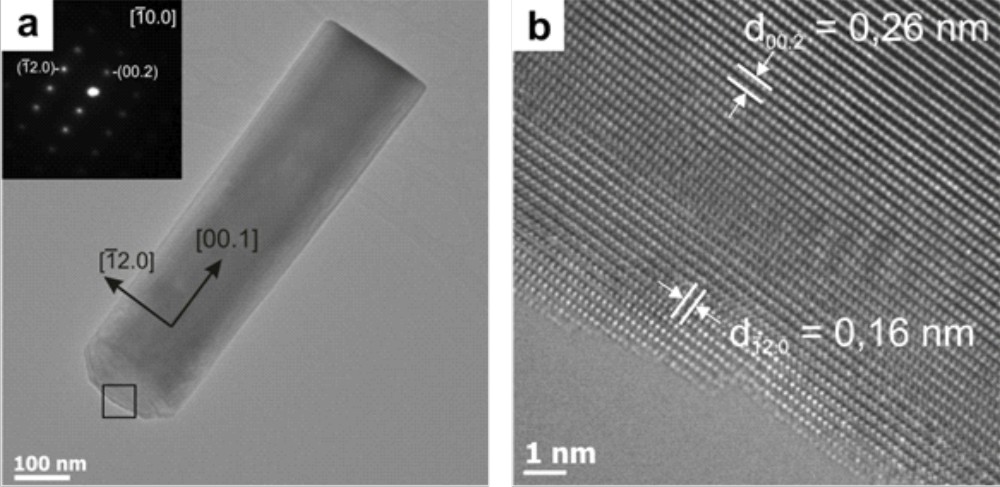

DescriptionZinc oxide (ZnO) nanorods of a very high quality are produced using a microwave assisted hydrothermal method on almost any type of the substrates. The material is produced in the growth process from an aqueous solution at a temperature below 80° C for 2-3 minutes. Currently, the maximum size of the substrate is 1.5 x 1.5 cm. Produced material is characterized by a high quality and low defects concentration. Low growth procedure blocks formation of oxygen vacancies. This innovative method was developed and patented at the Institute of Physics PAS.

Specification

ApplicationsDue to the known sensor properties of the ZnO, nanorods of this material naturally are applicable to gas and radiation sensors, wherein the developed surface is needed. ZnO nanorods are also used in photovoltaics, where they can act as both anti-reflective layer and n-type partner in the junction. Moreover, due to the piezoelectric properties of ZnO, these nanorods are an ideal substrate for the measurement of surface-enhanced Raman spectroscopy (SERS).

Patent applications: P.402755 (13.02.2013), P.402753 (13.02.2013), P.400284 (7.08.2012), P.398029 (6.02.2012) |

| |||