Oxide composite layers | ||||

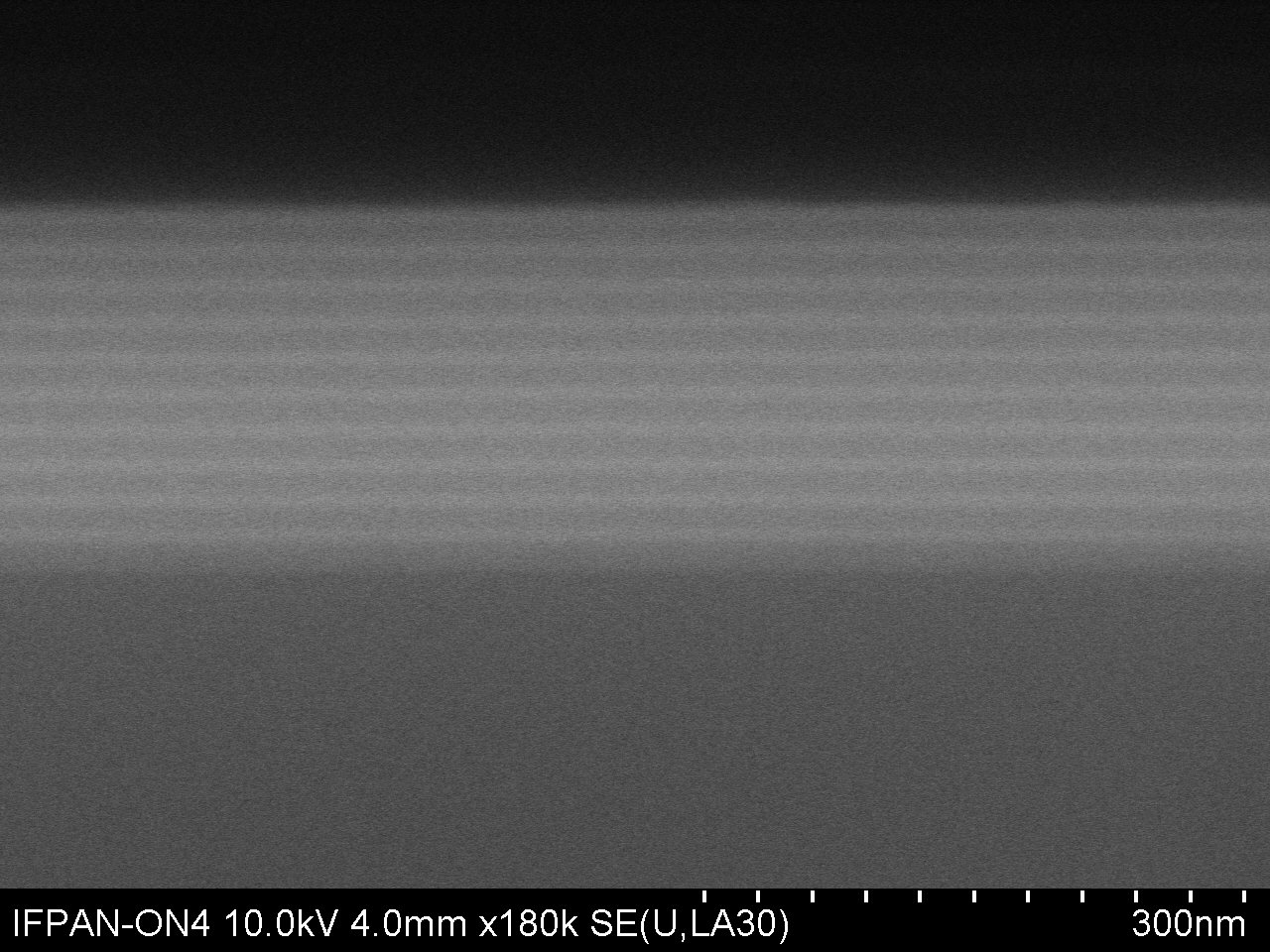

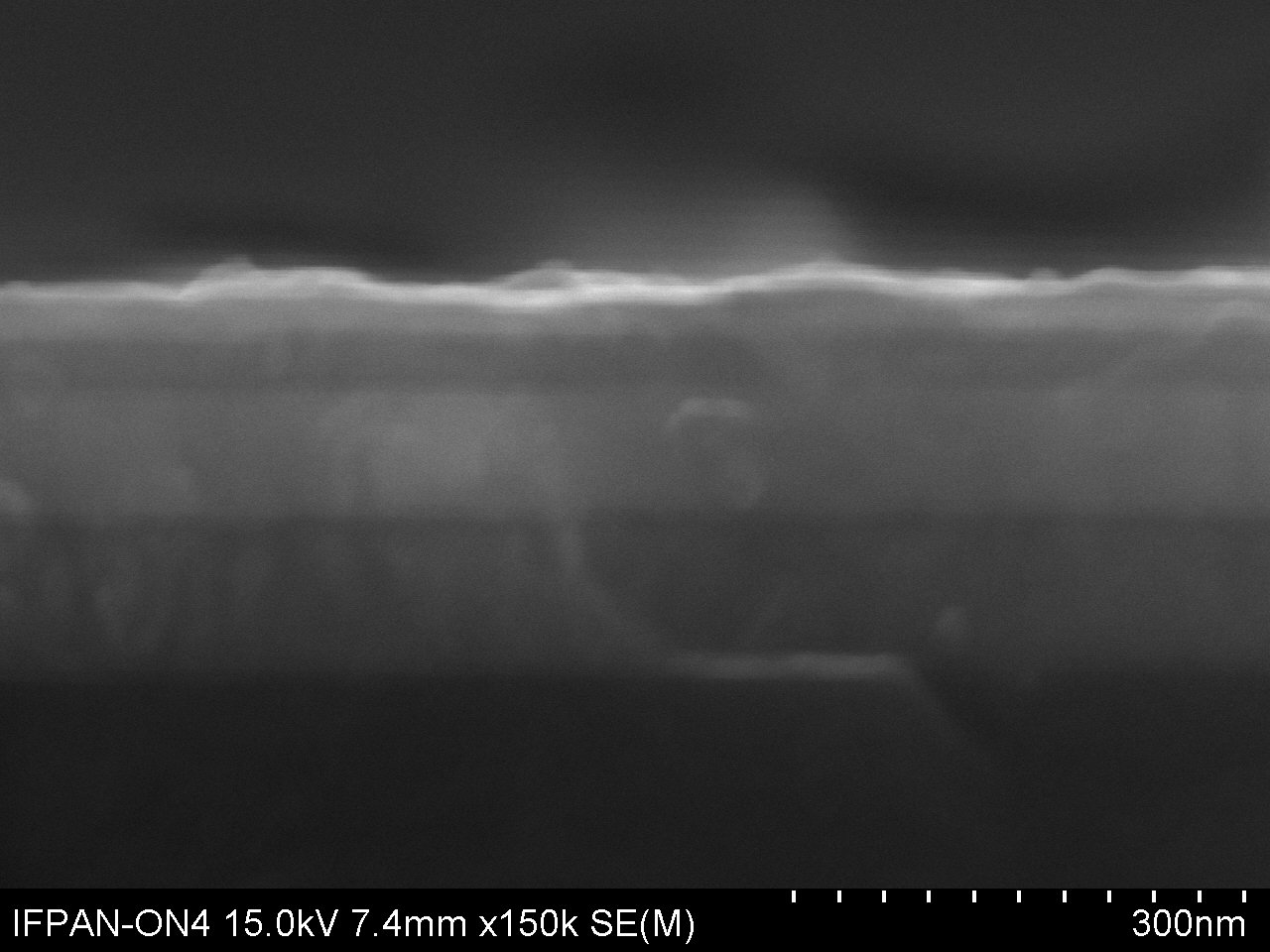

DescriptionOxide composite layer are obtained by atomic layer deposition (ALD) on any substrate like Si, GaN, SiC, graphene, SiO2, natural and artificial materials, in particular on the fiber surface, etc. Materials are formed in a double exchange chemical reaction between two reactants (precursors) such as a oxygen precursor and a metal precursor. The composite layers may consist of spacers of oxide materials having a thickness of nanometers. Oxides can be grown at the temperature range from 25°C to 300°C depending on the precursors used. The maximum size of the substrate is 20 cm of a diameter. Specification

ApplicationsThe wide band gap oxides are characterized by desirable optical, electrical and structural properties (for example: different values of the refractive indices, different electrical properties, different values of energy gap, etc.). Due to such properties the best solution is to use composite layers as insulators in the electronics, a variable resistance materials in electronic memories, as optical coatings having different refractive indices in lasers and microscopes and as protective layers.

Patent application: P.395639 (13-07- 2011) |

| |||